Industry 4.0 → 5.0 — When Systems Begin to Collaborate

Cognitive Index 05 - From automation to awareness — the shift from efficiency to empathy.

Cognitive Index | By Beyond Coordinates

Δ ▽ ⧋

Teaser

Industry 4.0 was about connecting machines.

Industry 5.0 is about connecting decisions.

I think this decade marks the point where intelligence stops being about control and starts being about coordination.

The Turning Point

For the past decade, Industry 4.0 focused on visibility — sensors, dashboards, and predictive analytics that helped businesses see what was happening. But I believe visibility without interpretation has limits. As the volume of data grew, the real challenge became making sense of it fast enough to act.

That’s where Industry 5.0 steps in — to turn information into understanding and systems into collaborators.

How Industry 4.0 Evolved to Industry 5.0

In the 4.0 world, Siemens MindSphere, PTC ThingWorx, and Bosch IoT Suite gave factories a single view of their operations.

In 5.0, that same infrastructure now enables adaptive work cells, where cobots like ABB GoFa and Universal Robots adjust to human input in real time.

Digital twins moved from simulation to reasoning.

Dassault 3DEXPERIENCE and NVIDIA Omniverse models now test ergonomics, energy impact, and material resilience before a prototype is built.

Predictive maintenance went from “detect and alert” to “anticipate and adjust.”

Edge AI platforms such as Hitachi Lumada can fine-tune machine settings automatically to prevent downtime.

Supply chains evolved from static planning to dynamic response.

o9 Solutions and Blue Yonder integrate live market and weather data to shift production or routing before disruption hits.

I think these examples show a steady pattern — automation turning into assistance.

The Human Equation

Industry 5.0 isn’t a rejection of automation; it’s the next layer — where people and machines share the same workflow.

AR systems like HoloLens 2 or Varjo XR now help operators learn faster, troubleshoot on the spot, and reduce training time by up to 30 percent.

3D printing platforms such as HP Multi Jet Fusion or Formlabs allow on-demand customization, shrinking inventories and design cycles.

And low-code environments — Tulip, Mendix, Zoho Creator — let production engineers build apps for quality or downtime tracking without waiting for IT.

I believe this is where the real shift happens: industrial systems designed around human capability, not human compliance.

Regional Playbooks

United States: building algorithmic scale through AWS IoT, NVIDIA Omniverse, Rockwell FactoryTalk. Advantage: platform ecosystems; focus: AI-driven productivity.

China: centralizing speed through Haier COSMOPlat, Huawei Cloud AI. Advantage: fast replication; focus: AI manufacturing clusters.

Europe: balancing sustainability and standards through Siemens, Bosch, Schneider Electric. Advantage: ethical automation; focus: human-centric policies.

India: scaling inclusively through Addverb, CynLr, Grene Robotics, and L&T Tech. Advantage: affordability with intelligence; focus: diverse adaptation and frugal cognitive systems.

I wish to forecast that India’s strength will not be in volume manufacturing but in adaptive system design — where flexibility becomes a competitive advantage.

Areas of Acceleration

I foresee five areas reshaping industrial growth over the next decade:

Collaborative Workcells – human-robot cooperation that increases output per square foot.

Adaptive Factories – lines that switch products overnight using digital twin feedback.

Resilient Supply Networks – AI models predicting risk and adjusting procurement in real time.

Sustainable Loops – production systems that reuse materials and measure emissions continuously.

Operational Interfaces – no-code dashboards giving front-line teams control over data and process changes.

These aren’t theoretical. They’re the next growth engines for manufacturing and logistics worldwide.

The Cognitive Index Analysis

Every Cognitive Index isolates one question:

what happens when systems begin to understand the impact of their own decisions?

Industry 4.0 optimized for performance.

Industry 5.0 optimizes for perception — awareness of outcomes beyond output.

I think this shift can be measured across three dimensions of maturity:

Intelligence → Empathy: Machines move from efficiency to comprehension.

Metric: reduction in operator overrides and incident escalation rates.Integration → Coordination: Data systems move from connected to synchronized.

Metric: percentage of cross-domain decisions (supply, energy, logistics) taken autonomously with shared context.Intention → Alignment: Organizations move from productivity to purpose.

Metric: ratio of sustainable output (per unit energy/material) against profit margin.

These are not abstract ideas — they are measurable signals of cognitive progress.

I believe the most advanced enterprises in 2030 will not just optimize throughput but also quantify clarity — how coherently people, systems, and goals align.

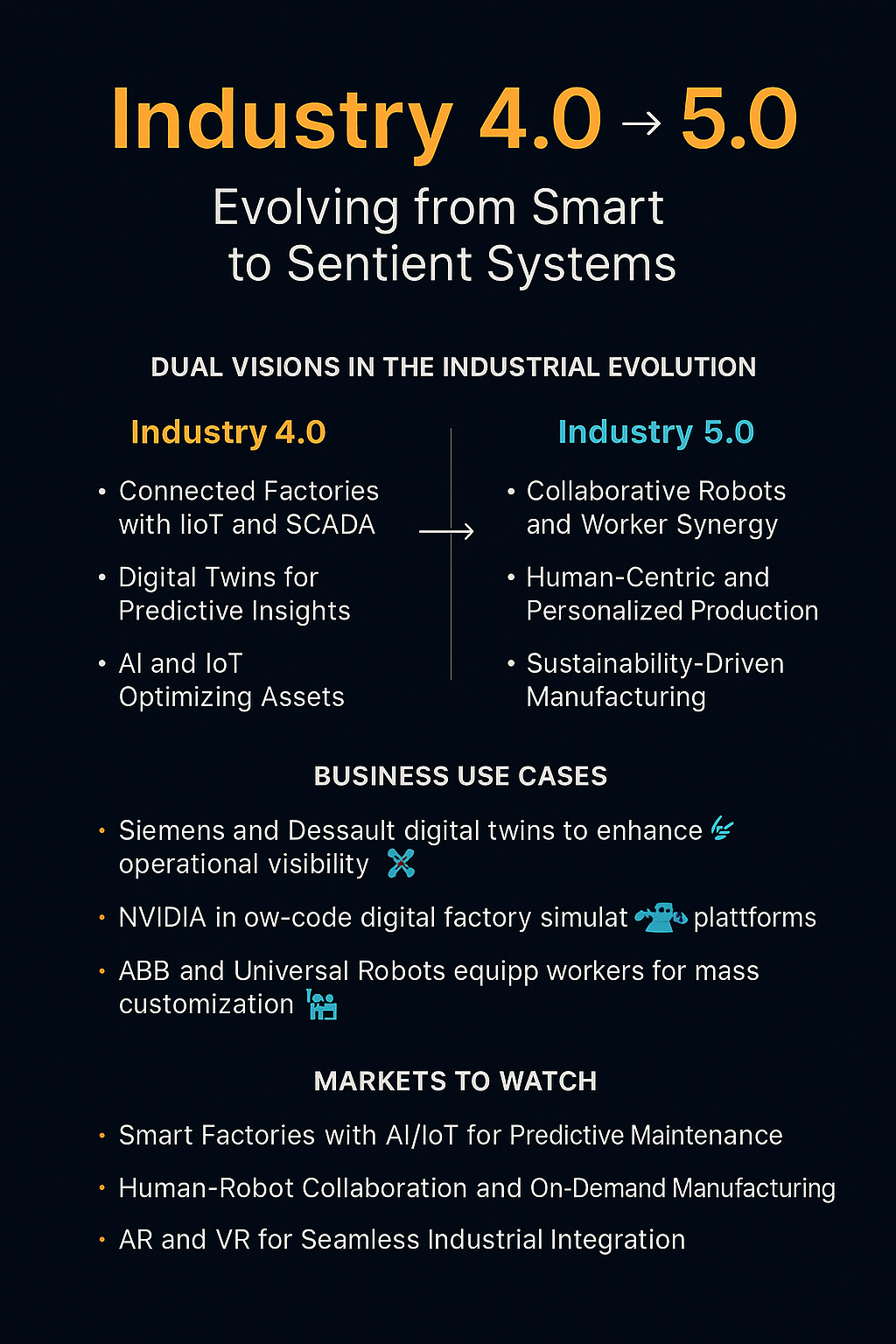

Visual summary of Cognitive Index 04 | Industry 4.0 → 5.0.

Tangible Business Outcomes

Throughput efficiency: real-time coordination between AI planners and human supervisors reduces downtime by 35%.

Quality and compliance: AI-assisted inspection reduces error by 60%, while maintaining full audit traceability.

Energy optimization: real-time carbon and energy accounting becomes a profit metric, not just a policy metric.

Workforce retention: human-robot collaboration reduces repetitive strain and increases engagement.

I think performance itself is evolving — not in speed, but in how quickly a system learns to improve without being told.

Bonus: Three Business Use Cases & Markets to Watch

1. Cognitive Maintenance Platforms

What began as predictive maintenance has become real-time self-adjustment.

Emerging players like Uptake, Augury, and Hitachi Lumada are creating closed feedback systems — machinery that regulates itself by interpreting vibration, temperature, and torque.

→ Market opportunity: $40B+ by 2030 as manufacturing plants digitize reliability.

2. Human-in-the-Loop Automation

Low-code AI copilots (Tulip, Augmentir, Poka) are redefining front-line productivity.

Operators no longer just follow workflows; they design them.

→ Impact: 2–3x faster process improvement cycles, higher autonomy at lower cost.

3. Adaptive Logistics Networks

Companies like Blue Yonder, o9 Solutions, and Llamasoft are blending external data — weather, geopolitics, demand sentiment — with manufacturing intelligence.

→ Impact: up to 25% inventory reduction, 15% cost optimization across distribution.

I believe these three arenas will anchor the measurable side of Industry 5.0 — where cognition turns directly into value.

Reflection and Forecast

Industry 4.0 taught us how to monitor; Industry 5.0 is teaching us how to interpret.

We built digital infrastructure — now we’re learning digital responsibility.

I wish to forecast that by 2030, the most valuable manufacturing companies won’t be the largest — they’ll be the most aware:

those who know exactly how, why, and at what cost every decision is made.

The next revolution won’t be industrial. It will be relational.

Sources

Siemens AG (2024) – MindSphere & Xcelerator industrial IoT suite and sustainability roadmap.

Dassault Systèmes (2024) – 3DEXPERIENCE Twin Strategy for adaptive manufacturing.

NVIDIA (2025) – Omniverse Enterprise for Digital Factory Simulation.

ABB Robotics & Universal Robots (2024) – Collaborative robotics deployment in high-mix assembly.

Hitachi Vantara (2024) – Lumada edge-AI predictive maintenance and cognitive automation case studies.

World Economic Forum (2025) – Global Lighthouse Factories Report — benchmarks on human-machine collaboration and energy optimization.

Δ ▽ ⧋ | © Beyond Coordinates 2025

All rights reserved.

Part of the Cognitive Index series by Beyond Coordinates — mapping how intelligence, systems, and purpose are reshaping modern industry.